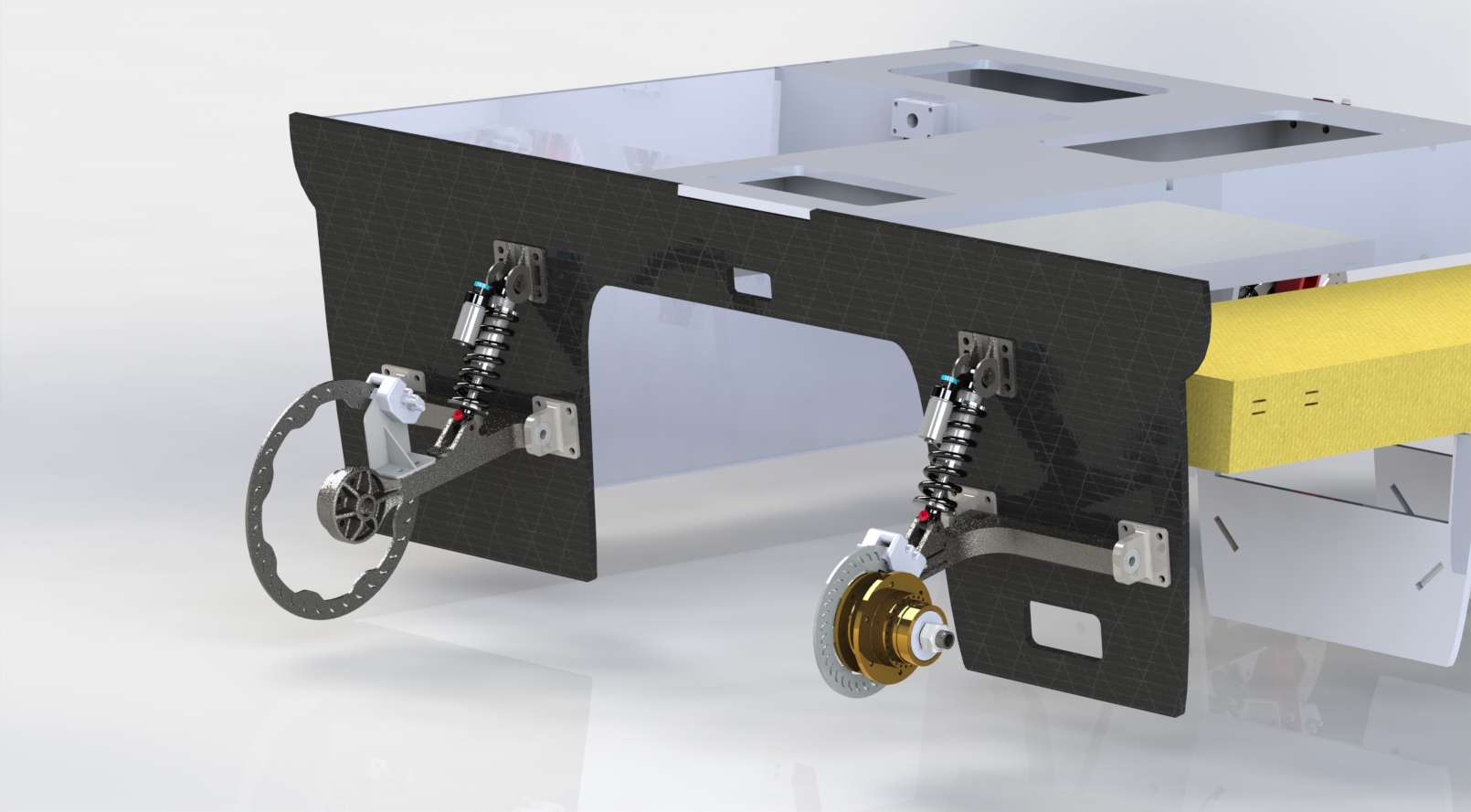

As Responsible Engineer (RE) for the rear suspension, I was in charge of the assembly of the rear suspension. The rear suspension consists of a number of CNC-milled aluminum and steel parts held together using bolts, flex lock nuts, and ball bearings to maintain a rigidity with respect to the carbon fiber rear panel of the chassis. The back suspension is meant to absorb impacts from uneven roadway, and is also important for mounting the shock absorbers, braking system, and wheel packages.

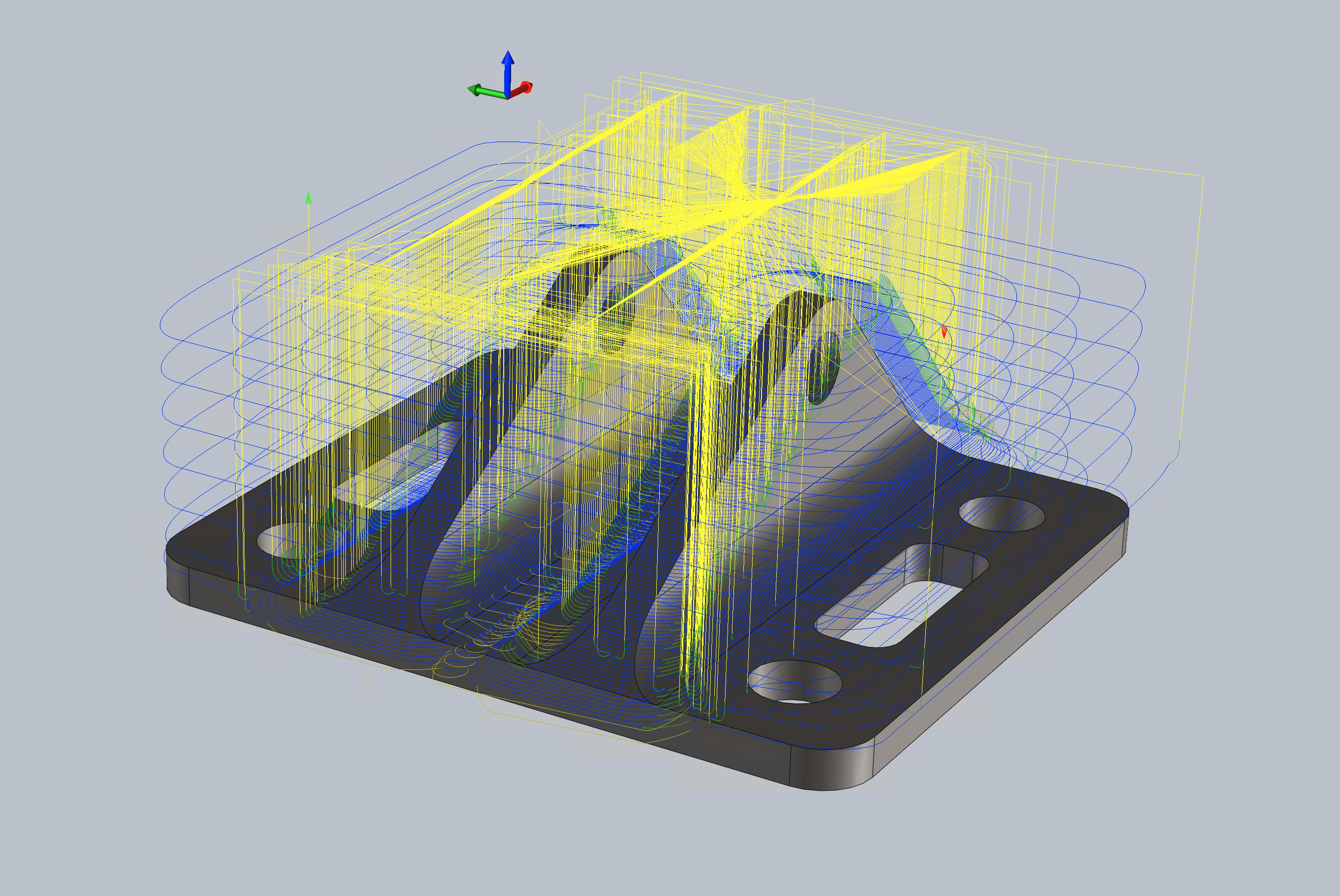

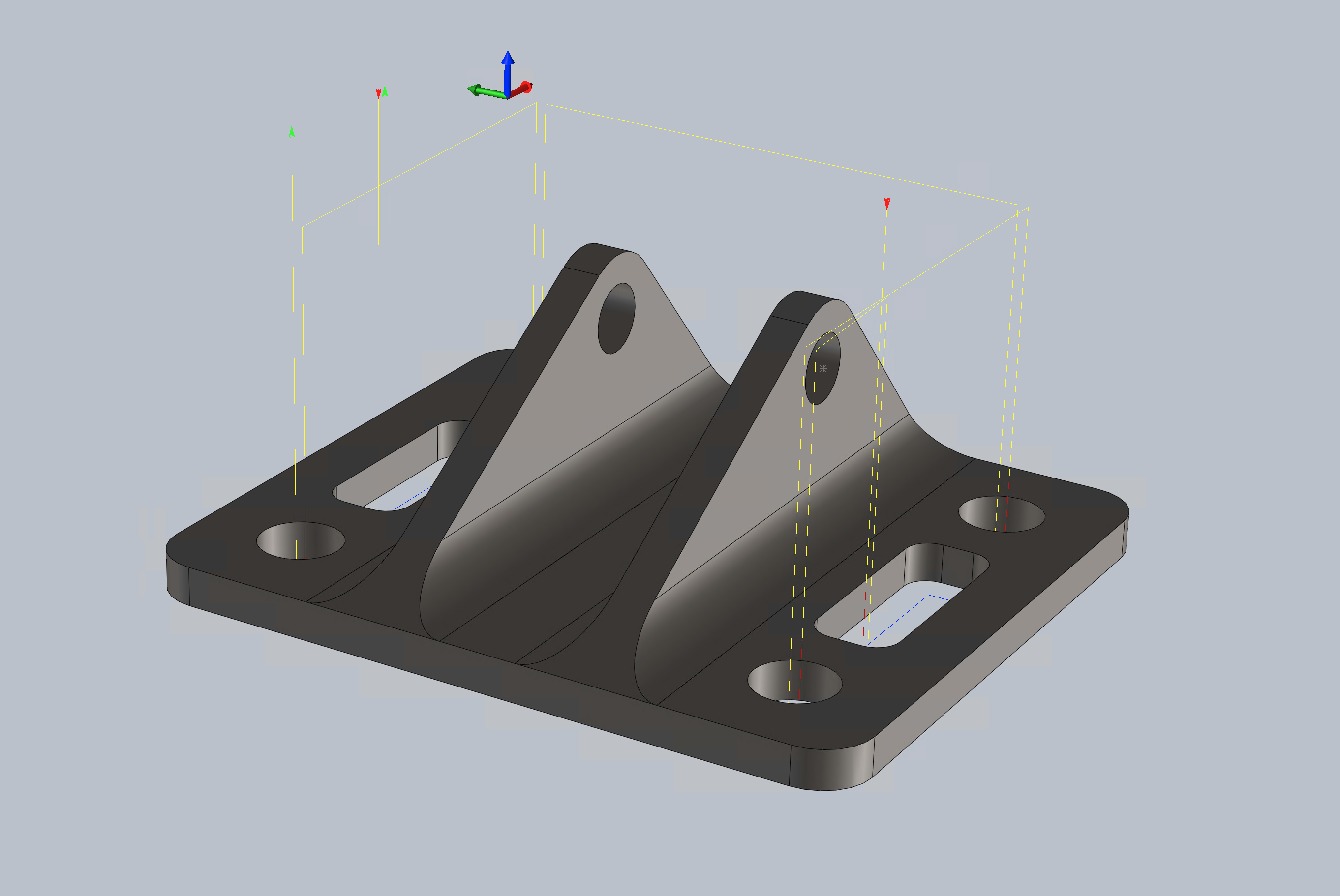

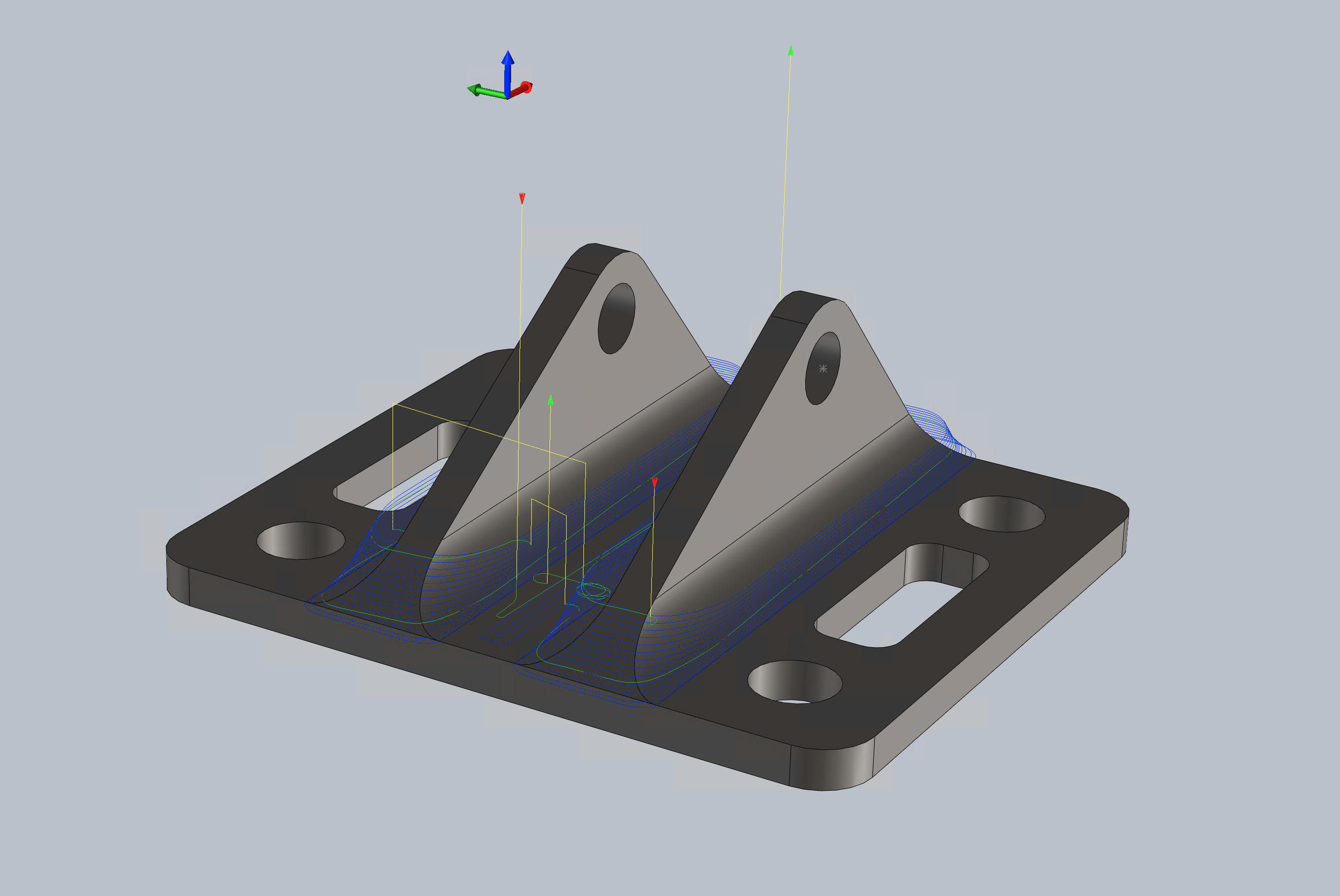

I was also responsible for machining the upper shock mounts (pictured below) using a Prototrak 3-axis CNC mill. I used Autodesk HSMWorks in Solidworks to make the toolpath. Starting with the blocks of aluminum stock, I manually faced the block to the correct size and drilled the lateral bolt hole. Then, I ran the toolpath to make the part.